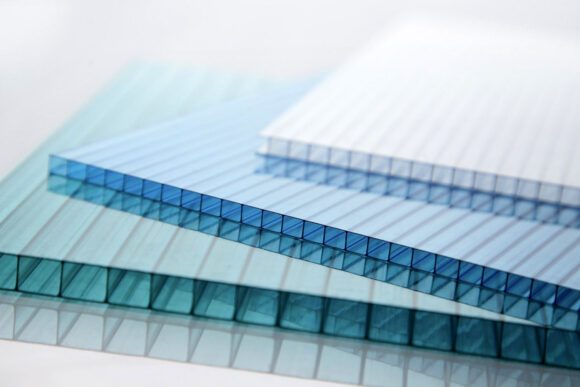

Today, polycarbonate is widely used in construction, in the manufacture of translucent structures and in the decoration of buildings. Of the entire selection of materials, cellular polycarbonate with UV protection is most popular.

This is due to the fact that the panels are often used for the construction of greenhouses, conservatories, canopies etc. This structures are constantly exposed to sunlight and other adverse factors. And the presence of special protection level their negative impact.

Why does polycarbonate need UV protection?

Sheets that do not have protection, as a result of constant exposure to sunlight, lose transparency, become yellow, brittle. Ultraviolet light destroys polymer bonds. As a result plastic loses its original characteristics – plasticity, resistance to mechanical stress, and bearing capacity. Over time, the plates are destroyed and the design requires a new coating and additional costs.

In addition, among the many uses of polycarbonate, there are areas in which the presence of a protective coating plays an important role. For example, in the construction of greenhouses, a balance is needed between light transmission and the ability to retain rays of a certain spectrum, the excess of which can harm plants.

When using sheets for greenhouses, conservatories, the presence of a UV filter is also important, which transmits light, provides lighting that is comfortable for vision, but delays 280 nm wavelengths, which can have a harmful effect on human health.

Therefore, the presence of high-quality UV protection is one of the main characteristics of polycarbonate and an important selection criterion when buying.

Which side is the UV protective layer applied to?

In practice, polycarbonate sheets are protected in two ways:

- Adding stabilizing components to raw materials.

- Drawing on a surface of a protective layer.

The amount of stabilizer that is added to the raw material does not provide the necessary degree of protection for the operation of the material for more than 1-2 years.

In addition, the granular composition reduces the strength of polycarbonate. The reflection of rays occurs at a deep level. So they partially come through the structure of polycarbonate and destroy it. Sheets with protection “in bulk” are cheaper. But after about a year they lose their original physical properties and aesthetic appearance.

UV protected polycarbonate for greenhouse

UV protected polycarbonate for greenhouse

The most reliable method of UV protection is applying the film to the outside of the panels with a coextrusion method. In this case, the concentration of the substance, the uniformity of its distribution on the surface and the thickness of the layer are important. For example, to ensure the service life of the panels of at least 14 years, the layer thickness should be 15-30 microns.

Unlike stabilizers, which are added to raw materials, the film can be seen. For this, a special optical additive is used, which gives the surface a bluish fluorescent color. This shade is clearly visible under an ultraviolet lamp. And if you use a special microscope, you can accurately determine the thickness of the layer.

On the side with the UV filter, manufacturers mark. Therefore, when installing sheets, it is necessary to ensure that it is facing outward, towards the sun.